water refinery

water refinery

Surface waters often have a greater diversity of pollutants than groundwater, and therefore the purification processes may be more complex for these waters. Most aquatic surface waters are more than those set by drinking water standards. However, high-speed currents may have larger suspended matter, but more solids are found in colloidal proportions, and for separation, use of purification processes needed.

Water purification steps

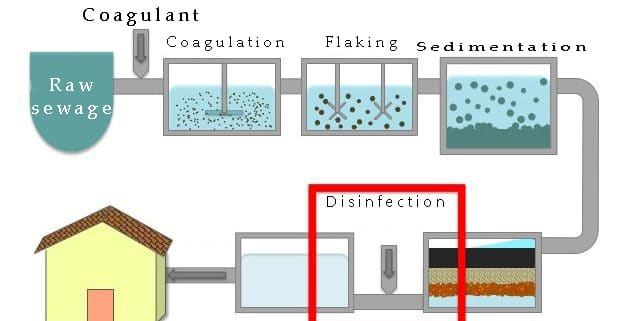

The water purification processes in the order of placing the units in the water treatment plant are as follows:

- Pond

- Dirt stuck

- Basic Chemical Decontamination

- Preliminary sedimentation

- Surface water grids

- Aeration

- Coagulation and flocculation

- Stiffening

- Disinfection

- Storage

Pond

To clean up surface water, it is usually first to remove water from a source called a reservoir from the source and transfer it to the treatment plant. The basin is usually a building unit or concrete building used to provide calm and free flowing water with a better quality than the water source. The water provided through the pond is smoother than the original source and has a better quality. . For this reason, the catchment area should be located on the upstream of the city’s water currents and should never be flooded in areas with flowing eddy current. In the area of the basin, it is usually done using gauze brushes and in general a simple physical cleaning is done.

Dirt stuck

The water treatment plant has several units for solid separation of water. Selecting a specific unit or a combination of different processes to remove suspended solids is required for solids characteristics, concentration, and degree of water purification. For example, very large and heavy solids can be separated by grid extraction grids or fine grids, and they are placed in solids smaller and colloids are removed by removing chemicals and dissolving. The employment objectives are as follows:

- Separating and removing large raw materials loaded with raw water, which can affect the efficacy of subsequent treatment processes and make them difficult to function.

- Protecting the next unit of the refinery against large objects that can cause blockages and damage in some equipment.