MBBR Wastewater treatment System

MBBR Wastewater treatment System

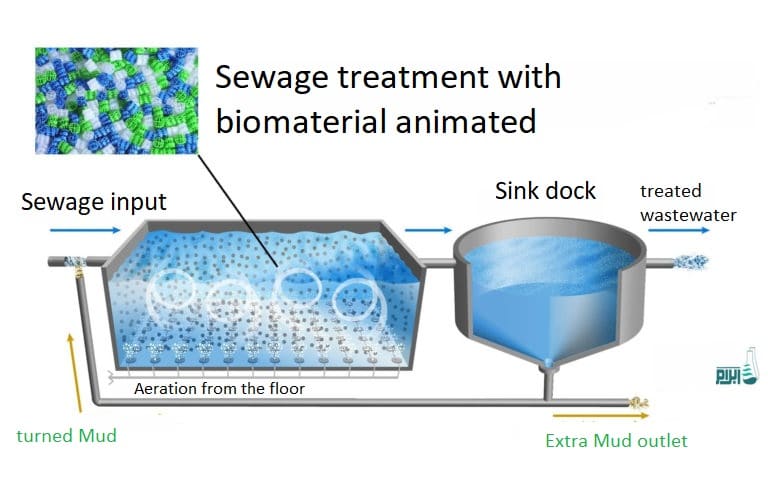

The sewage treatment with a mobile bed, or the MBBR method, is an effective method for treating wastewater. use of this method for the removal of organic matter in sewage has a high efficiency and the process quickly reduces biodegradable biodegradable materials.greater the need for higher quality wastewater for the conservation and preservation of surface water has led to more and more tendency towards this system.During the last decade, the MBBR system has been successfully implemented due to its positive attributes for sewage treatment of factories such as paper and pulp industry, cheese industry, refineries and slaughterhouses, waste water from paper mills and municipal sewage.

Application of sewage treatment by MBBR method

The MBBR wastewater treatment metal package is manufactured by Abram Company for the following sewage:

- Sewage treatment of residential and office complexes

- Sewage treatment of hospitals and clinics

- Wastewater treatment of factories and industries

- Sewage treatment of military centers and terminals and airports

- Sewage treatment for hotels and hotels and resettlement centers

- Refining of food and dairy factories (considering the quality of sewage)

Advantages of the MBBR Wastewater Treatment Package

- Provide treated sewage output in accordance with EPA standards

- Small and fast dimensions

- Possibility to transfer the package after installation

- The least amount of bad breath is when you have the right path

- Simple navigation and maintenance

- The concentration of sludge was low

In this method, it is not necessary to build a sedimentation basin for initial sedimentation, and it is desirable to aeration directly after passing from the garbage collector and the granulator. Of course, in a hospital, the aeration after the balancing pond is also very good.

The volumetric flow rate of the MBBR treatment method is very low because biological masses have long been in contact with suspended media and oxygen and organic wastewater is more widely used by microorganisms. In the wastewater treatment package (MBBR) Typically, the percentage of active sludge from the final settling pond is returned to the aeration pit. If not carefully used, then the production of untreated sewage would be as good as it would be odorless.

The research was conducted on the removal of phosphorus in the MBBR system in the treatment of mobile wastewater for dairy industry sewage treatment, and it was observed that the MBBR system was capable of increasing the amount of phosphorus from 29 mg / L to 0.36 mg / L. In addition, the MBBR system requires less space for installation, and fewer problems with start up and downtime, and also increases COD removal rates.

The MBBR treatment of sewage treatment, from 2006, was used to remove nitrogen from low-temperature dairy wastewater and concluded that the MBBR system could be 50-60%, nitrogen and COD, 70-40% It eliminates the ability of the system to complete the nitrification process completely. In 2006, a fluid bed reactor was used to decontaminate textile sewage, and it was concluded that the system was able to decontaminate wastewater at a low cost. Meanwhile, methane-rich biogas is also produced, and generated wastewater finds the high biological degradation potential of aerobic microbes.

Sewage treatment unit packages by MBBR method

garbage collector

The function of the collecting gerbage that is placed in the EAAS method before entering the sewage treatment plant In order to remove floating or immersed solids in the sewage.deleting the materials depended on the size of the fountains and the characteristics of the solids in the sewage system.Typically, metal that use there is made of steel or galvanized ST37 steel.Aeration parts, secondary sedimentation and chlorination, sludge reservoir that are stacked together in a package.The entire body of the Package is Steel ST37 that The floor of package with steel plate ST37 with a thickness of 8 mm and a wall with a thickness of 6 mm.

Aeration

Aeration system to the sewage worked by Aeration Blowers ,The air produced by the blowers is transmitted through plumbing to the floor of the aeration pond.Then, using diffusers, this air is transferred to the sewage and the biological separation stages of the sewage are discharged and the wastewater compounds are decomposed.

PACKING MEDIA ARAB DOWN

PACKING MEDIA PACKAGE or PACKING MEDIA FLOAT includes various types of caldens, capers and lipfords, each of which changes in suspended bed in an aeration tank of the MBBR process.

Secondary Sedimentation

After aeration, the sewage enters the drainage basin to process sedimentation and sludge separation from the treated effluent.

Chlorination

The chlorine injection package consists of a tank of 300 or 200 liters with a mixer that is injected into the wastewater after mixing water and calcium hypochlorite.

Sludge storage tank and Sludge return

The amount of sludge added from the dock to the sludge storage tank is transferred. Certain amounts of sludge are transferred from the sediment reservoir to the aeration pond. The goal of the amount of returning sludge is to maintain a sufficient microbial concentration to stabilize the organic matter entering the aeration tank.

Electrical panel

In order to control different parts of the sewage treatment package, such as blowers, pumps, chlorine dosing, an automatic switchgear is required to control all parts of the package and all processes are automatically depleted.